Fascination About Plastic Bottle Suppliers

Table of ContentsPlastic Bottle Suppliers Things To Know Before You BuyThe Single Strategy To Use For Plastic Bottle Suppliers

RIM is most often made use of in the automobile industry due to the fact that it produces light-weight parts that have a stiff skin. This skin is easily repainted to make body panels, dashboards and also various other vehicle components. Nonetheless, thermoforming plastics won't function in this procedure. Instead this process calls for thermosetting plastic. Thermosetting plastics go through an irreversible chemical reaction inside the mold and mildew (plastic bottle suppliers).When the chemical response is done the plastic establishes into its final kind. Tooling costs for models are fairly low, while production tooling is moderately expensive. The major expense is in the product, keeping in mind that the resulting component needs to always be finished, usually with a urethane-based gel layer or by paint, so the process is much more labor intensive which increases the item price.Vacuum casting is a fantastic selection for making a small number of top quality rapid models without a huge investment in devices or material. When the master is eliminated, a dental caries is.

developed inside the mold and mildew that can now be full of plastic resin to develop a duplicate of the original. Vacuum cleaner pressure is used to draw air out of the mold and mildew so that it fills totally without any air bubbles. In this procedure, the surface area coating quality and also detail are outstanding as well as pourable resins can copy numerous engineering qualities of plastic. This is a kind of vacuum creating, where thin or thick gauge plastic sheet is placed over a die, heated to a temperature level that enables the material to become flexible, then is stretched over the surface of the die while vacuum cleaner pressure draws the sheet down and into its last form. It's commonly used with examples as well as prototypes of thin-walled, hollow-bodied components. In industry, it's utilized for plastic mugs, covers, boxes and plastic clamshell product packaging, along with for car body parts in thicker gauge product. Only thermoforming plastics are suitable for this process. The raw material is pre-heated as well as put inside the open cavity of a die. This procedure is excellent for rubber keypad switches, gaskets, O-rings as well as other soft, pliable thin-walled components. It's reasonably inexpensive and wastes little product, although regulating the uniformity of the ended up item can be tough as well as much treatment needs to be taken in the prep work of the first mold style. Star Rapid offers a range of services to help you obtain exactly the plastic or rubber components that you need for your project. When we grab a drink in the grocery shop or from a vending device, we're normally considering what's inside, not the container holding it. Yet an understanding of just how plastic bottles are manufactured supplies a window into the method day-to-day things enter being. Comply with along for the journey that cold tea bottle extracted from the factory to your hand. Bottling firms have a difficulty to satisfy when picking the product for their item. It should resist crushing while still being light adequate to ship financially as well as operate almost for customers. Concrete, for example, is a solid and also long lasting material, yet not specifically sensible for joggers on the move. It's a synthetic material used in the manufacturing of a large rage of commercial, clinical, as well as military applicationseverything from jewelry to boat sails to polyester clothes. Polyethylene terephthalate starts as terephalic acid as well as ethylene glycol. A chain reaction is then manufactured in between this acid.

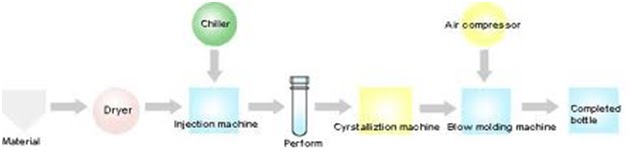

and also type of alcohol to produce oil hydrocarbons. Chains of the petroleum hydrocarbon particles are after that polymerized, or networked, to form the ANIMAL. ANIMAL is called a" thermoplastic polymer, "which suggests that its manufacturers can modify its chemical formula to produce either a transparent or color product. When this versatile product Homepage is created, plastic bottle production can begin. PET is delivered to makers in the form of small whitish-clear pellets that appear like the vital organs of a bean bag, or packaging product. These are then put into a heated container which has a reciprocating screw. The material pellets are melted to regarding 500-600 degrees Fahrenheit, and also the screw shoves the now-liquid ANIMAL right into a mold. In order to make the process extra constant and also reliable, the mold and mildews are cooled to just below half that of the home heating temperature between 190-230 degrees Fahrenheit, depending on.

Not known Incorrect Statements About Plastic Bottle Suppliers

the density of the mold and mildew. As the PET's temperature level declines, it ends up being a strong once again, and starts to take the same form of the mold. The ANIMAL is currently in the form of a lengthened, hollow tube, anywhere in between. 75 as well as 6 millimeters thick. The previous PET DOG pellets are now ready to come to be more recognizable as a plastic bottle.

The thin tubes are referred to as a" parison" or a" preform. "They look like vast examination tubes with screw tops waiting for a cap. find more information plastic bottle suppliers. In case the manufacturer calls for non-traditional container forms, there's an additional step at this moment while doing so. The parisons are given a complimentary ride on a conveyor belt on their way to a pre-warming session. Service technicians at the controls of infrared oven heat lamps, relying on the type of bottle needed, change the shape and thickness of the plastic. After that it's time to heat up again: The parisons are warmed once again, yet insufficient to meltjust enough to come to be malleable. A mandrel, or a read this steel pole a couple of millimeters thick, is inserted lengthwise inside the tube of FAMILY PET.